Liam and Eric recently returned from a trip to Kentucky in search of private barrels of Bourbon that will be sold exclusively at Bottles. The barrels will be in store within a matter of months, so to tide you over, here are a few highlights from the guys’ trip:

Day One

Welcome to Kentucky! We arrived just in time for an early lunch at Mammy’s Kitchen in Bardstown (Liam had a hot brown, and Eric had the country ham plate with fried apples and green beans, and “coffee”) before heading off to the Willett Distillery.

- Liam’s Hot Browns

- Mammy’s

The iconic Willett copper pot still is glorious. It was great to see how hands-on the distillery is in this highly technological age. Once made, all of Willett’s bourbon is transferred by hand into the barrels and weighed on a big manual scale (at the bottom of the photo) before being rolled into the rickhouse to age.

- Willett Still

- Filling The Barrels

- Off To The Rickhouse

Willett isn’t yet available in RI – but perhaps soon!

Next stop: Maker’s Mark, where Eric did a thorough inspection of the private barrels in their new warehouse. Dug into the limestone hills, it was built to house their barrels of Maker’s 46, which require a 9-week cold aging process to finish. The private barrels that are aged there are finished with a different type of oak staves for 9 weeks. The wax dipping line was pretty cool to see, though the lady on the left wasn’t all that impressed with Eric.

- Eric Inspecting Private Barrels

- Wax Dipping

Fun Fact: All of the trees outside of the distilleries are black. This is due to a whiskey fungus called Baudoinia. As barrels age in their warehouses, the liquid inside evaporates – the ‘angel’s share.’ This evaporate is full of ethanol, which Baudoinia feeds on. Since ethanol is denser than air, the angel’s share actually moves along the ground, and as soon as it hits anything moist (which there’s plenty of in the damp morning Kentucky dew) the fungus sticks and goes to work. Tree bark makes an especially good breeding ground. These lovely trees in bloom at Maker’s Mark show what we mean.

- Baudonia-covered tree

After a taxing day of bourbon tasting and dinner we were off to taste more whiskey! Here’s a shot from our barstool perch at Haymarket in downtown Louisville. That’s 300+ bottles of whiskey you see there, including the full cadre of Pappy and the antique collection, about 12 private barrel Four Roses, a bunch of stuff that isn’t made anymore and a lot more. We tried their own private barrel of Four Roses (picked by the Haymarket staff and Jim Rutledge the day before he retired). We needed a “calibration” on Four Roses before we headed over to pick out our own barrels. Also, their “well” bourbon is Heaven Hill 6-year – only available in KY. We might have had to bring some back with us.

- Haymarket Bar

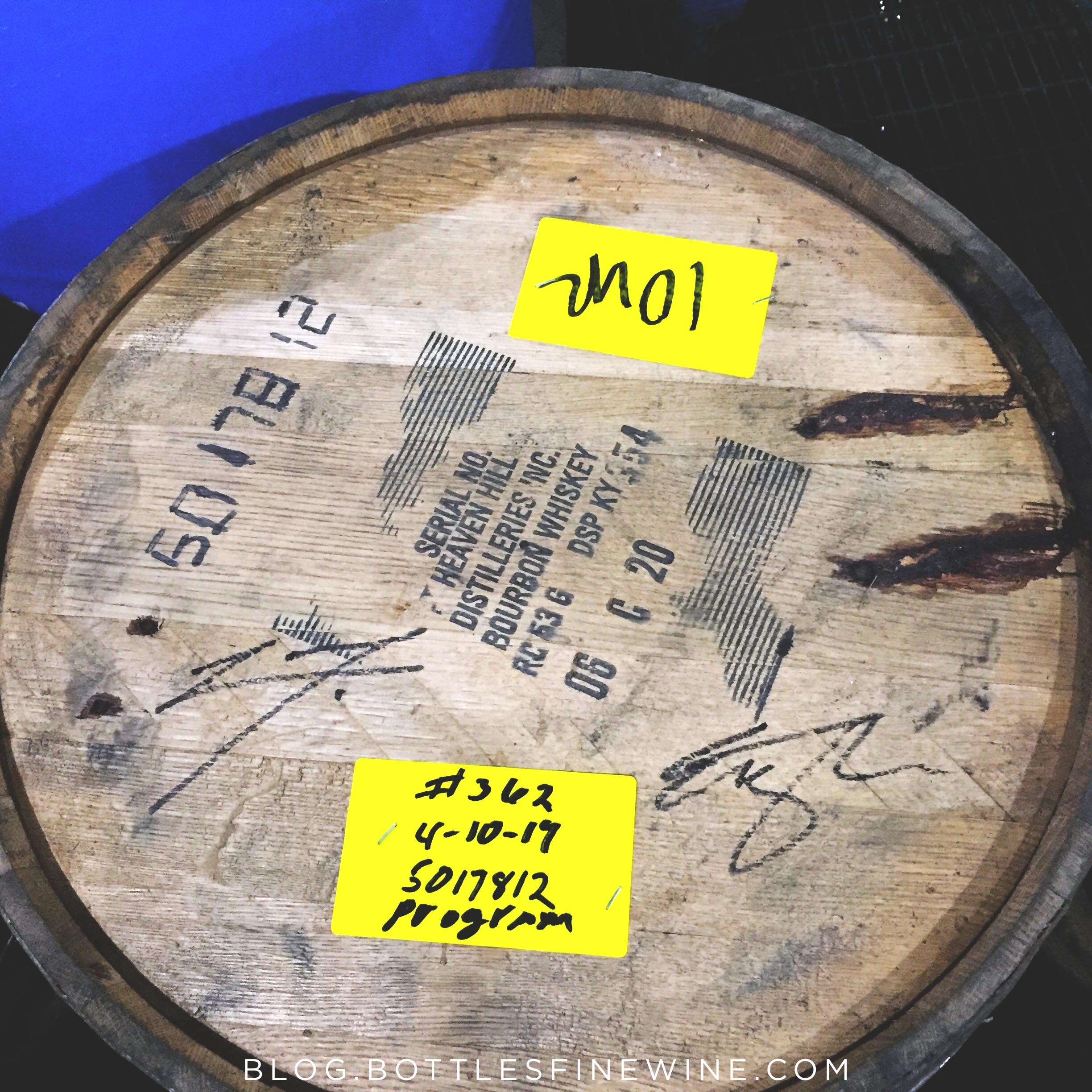

Day Two brought us to the Heaven Hill distillery. One of many highlights from our trip was stumbling upon our very own private barrel of Elijah Craig, number 5017812, which we selected from a slew of samples last month. Our guide was astounded – hundreds of barrels move throughout the facility each day – the chance that we were here on the one day that our barrel was in line for bottling was one in thousands. It’s bourbon kismet! It’s also how we found out it’s 10 years old. Not quite 12 years, but not too bad for some pretty good juice. We grabbed a sharpie and signed it. Keep your eyes open – it will be in store before you know it.

- Liam Signs Our Barrel

- Eric Signs Our Barrel

- Bottles’ Private Barrel

We then watched as barrel number 7673766 was rolled onto the line to be filled with new make whiskey. Once filled, it was carted off to the rickhouse to age anywhere from 4 to 30 years. Heaven Hill numbers their barrels sequentially, so this tells you they’ve produced over 7 million barrels. They come in one door to be filled, and robots pack them onto a truck to be moved to the rickhouse. The second photo below is a huge pile of what comes out after the barrels are dumped. It’s bits of charcoal from the charred barrels in which the bourbon was aged that need to be filtered off before bottling. It was still damp from however many barrels were dumped that day, and smelled amazing.

- Barrel #7673766

- Heaven Hill Barrel Char

Another astounding sight was that of the distillery warehouses themselves. The shot below is of just 4 of the 53 Heaven Hill rickhouses. The photo shows 7 stories of bourbon barrels, thousands of barrels in each – and these aren’t even the largest on the property. Over a million barrels are aging at Heaven Hill right now. These rickhouses caught on fire in 1996, sending rivers of flaming bourbon cascading down the hill, exploding barrels shooting overhead like fireworks. It’s very difficult to give a sense of scale, but these things are huge – gargantuan behemoths of bourbon rising over the horizon as you drive through the Kentucky countryside. Our heads came to about halfway up the bottom row of windows. The smell in the air was quite literally intoxicating.

- Heaven Hill Rickhouses

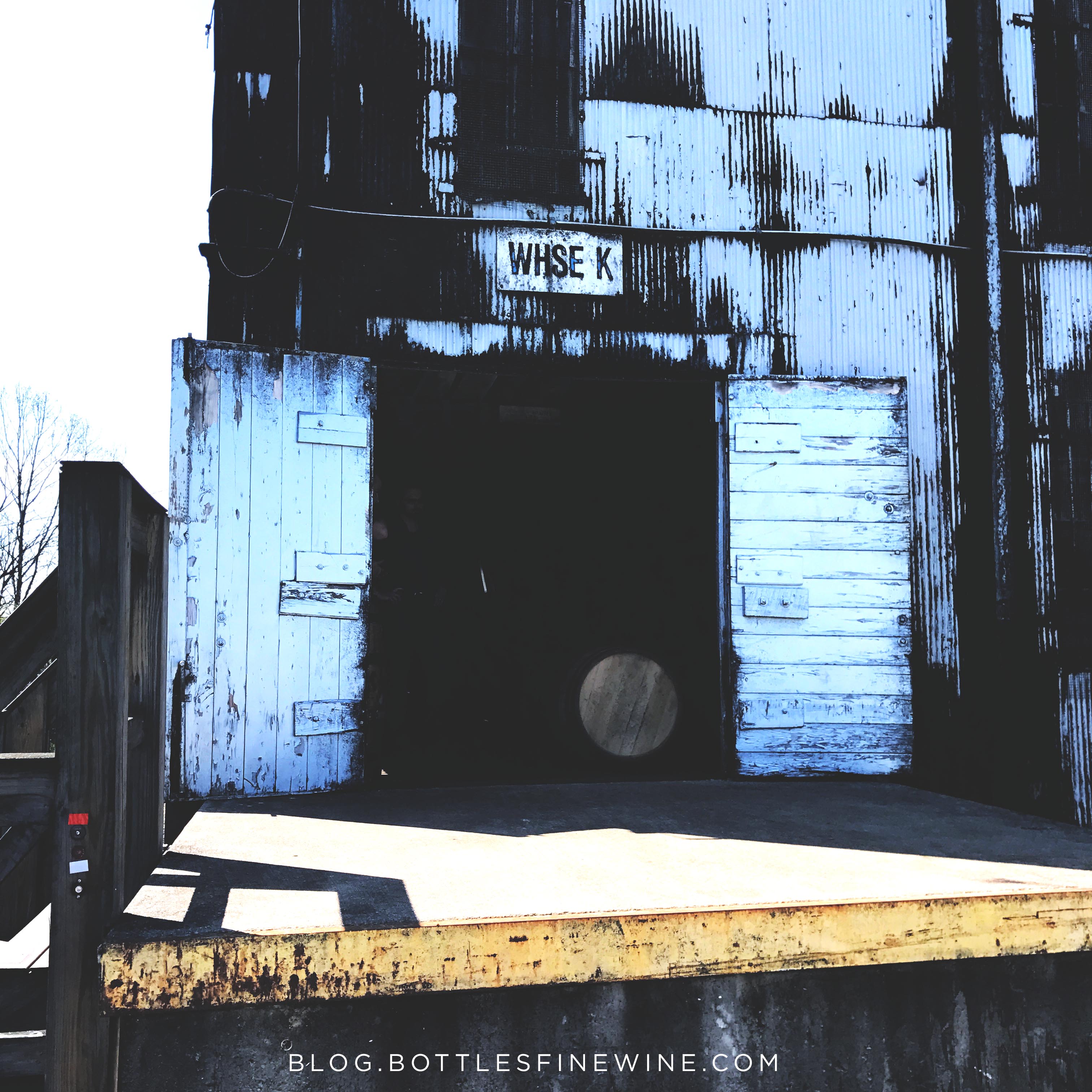

Next stop was to Jim Beam to select a barrel of Knob Creek. We got to open 3 samples ourselves, popping the bung out with a giant hammer, and sampling them fresh and raw right from the barrel. The difference in flavor from barrel to barrel is always surprising. Two of our samples were aging right next to each other, but couldn’t have been more different. We chose barrel C06B22, which was aged in Warehouse K (which abbreviated in the photo looks like “whiskey,” doesn’t it). The code on the barrel tells where the bourbon was made and its age: C is for the city of Clermont where it was distilled, 06 is for 2006, B is the second month of the year, and 22 is the day of the month. February 22, 2006. Our barrel is 11 years and almost 2 months old! It’s older than our store!

- Where Our Barrel Aged

We then went to Copper & Kings brandy distillery where (as we wrote about last month in our blog) the distillery pulses music via 5 major sub-woofers into their aging room. Unlike bourbon, brandy doesn’t like the temperature fluctuations that force the liquid in & out of the barrel staves – it’s too harsh for the delicate fruit flavors. In France, for instance, they will often rock the barrels by hand to agitate the liquid. At Copper & Kings, they use musical vibrations to jostle the booze in each barrel, allowing for more contact time with the wood. Sonic aging! You can see where they are aging brandy in ex-beer barrels as well. We were there on Al Green’s birthday, so it was Al’s tunes all day. That’s going to be some sexy brandy!

- Copper & Kings

Next stop was at Four Roses, where we selected two private barrels. While there, we had the great opportunity to hang out with Al Young, Four Roses’ newly-minted Senior Brand Ambassador. He’s a great guy to know, and he even co-signed the barrels we chose for ya’ll back in little Rhody. We chose the OESQ recipe, one that hasn’t gotten a lot of attention, but there are barrels that are just starting to hit their mark. We had a chat with Brent Elliot (who recently took over as Master Distiller from legend Jim Rutledge) about the barrel, which he personally selected as a sample for this program. He was excited that we chose it, and mentioned that several “Qs” had caught his eye recently (you can read more about the different Four Roses recipes and the significance of ‘Q’ yeast on their website. Our barrel has a nice interplay of flavors and is not too hot on the finish. It helps that it comes from warehouse M, rack 8, 6 high, so pretty much right in the middle of the warehouse – the sweet spot.

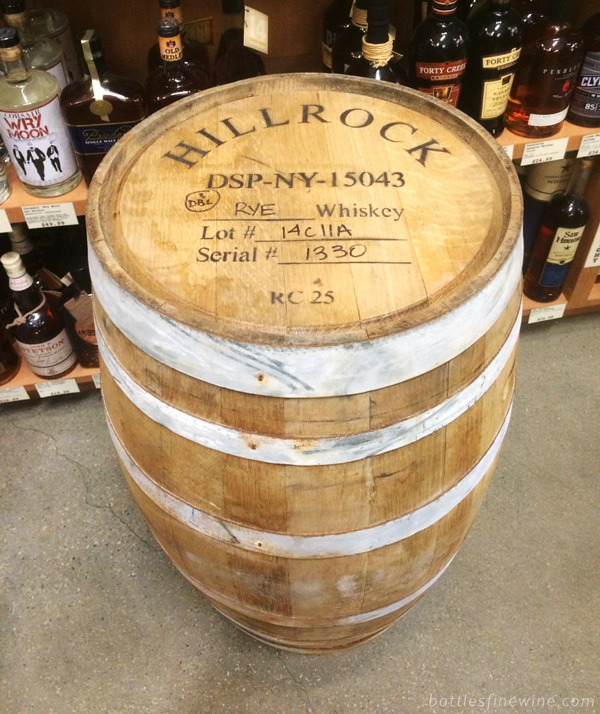

We mentioned that we bought 2 barrels…so what about the second one? It’s a surprise! But you’ll find out soon enough. We can’t wait for you to try them.

- Al Signs Our Barrel!

On Day Three we mozied over to the old Stitzel-Weller distillery – where Julian Van Winkle (the first Pappy) began the modern bourbon craze all those years ago. Though the distillery is in the process of being modernized, they still have some of the original buildings. Imagining Pappy walking through that exact door was pretty cool. The iconic Old Fitzgerald smokestack was great to see in person.

- Stitzel-Weller Distillery

- Old Fitzgerald Smokestack

We then went to the unbelievable Vendome Copper & Brass works, where almost 100% of the fermentation equipment for distilleries in the country (even that used by Rhody’s own Sons of Liberty) is made. The craftsmanship is amazing. Each still is a unique piece – and while they are 100% functional, they are complete works of art in and of themselves. The facility isn’t open to the public – we were so thrilled to have had a guided tour through it.

- Vendome Copper & Brass Works

- Vendome Copper & Brass Works

Later in the day we watched as artisans made barrels at the Brown-Forman Cooperage. The most important part of the bourbon aging process is the barrel, so to be able to see how they’re made was a rare treat. Brown-Forman makes their own barrels for Woodford Reserve, Old Forester, and Jack Daniels, among others. The barrels are charred with incredible heat for about 40 seconds. These barrels are right in the middle of their charring, and it was hot by the kiln. The char is what helps filter the bourbon and give it its distinctive golden caramel coloring. One of the most skilled jobs in the cooperage is that of fixing issues on defective barrels. This talented gentleman is replacing a split stave with a new one.

- Barrel Charring

- Stave Craftsman

We ended our trip with a visit to Buffalo Trace where we saw their indescribably huge (seriously – we couldn’t get a great shot) fermenters. They have 12 of them. Each is 3 stories tall and holds 92,000 gallons. Each. They were full & bubbling. The sheer size of them made us truly wonder why it’s so hard to get their bourbon – where is it all going? Or is it all still aging?

- Buffalo Trace Fermenters

The bottling line for Blanton’s Single Barrel is tucked away in a quiet corner of the distillery grounds. When the barrels are ready, they are individually vatted & proofed, hand bottled one-by-one, hand numbered, etc. It truly is a gem of a hand-made Bourbon. Wish we could get more of it at the store, but when you see the small number of bottles that each barrel yields, you can understand why it’s so hard to come by.

- Bottling line for Blanton’s

We couldn’t have asked for a better way to end the business side of our trip than a visit to ‘Bourbon Pompeii’. Not open to the public yet, this is the excavation of the ORIGINAL O.F.C. distillery from 1873, built by Colonel E.H. Taylor, Jr. The history is amazing. Those big square holes were 12 copper-lined big fermentation tanks, and there is some sort of cistern (no one knows what that was for yet). It was a step into history that few get to see.

- Bourbon Pompeii

- Bourbon Pompeii

We couldn’t leave Kentucky without a trip to a race track! Before heading to the airport we made a pit stop at Keeneland for the Maker’s 46 Mile. Liam bet on horse 6, ‘Conquest Panthera’ & won $2! Eric bet on horse 4…

- Liam’s a betting man

- Winner! Winner!

- Eric’s not a betting man

We saw a ton during our time in Louisville, more than we have room to share here. We had lovely visits with the Alltech Brewery & Distillery (makers of the popular Kentucky Bourbon Barrel Ale and Town Branch Bourbon), Woodford Reserve, Against the Grain Brewery, and other hot spots around town. We tried some amazing bourbons, met some very cool people, and found some very tasty whiskey to bring home and share with all of you. Keep your eyes peeled over the next few months for the arrival of our private barrels, and your own taste of the best Kentucky has to offer.

###